| Conveying Speed | about 2.5-6m/s |

| Conveyor Pressure | 600-1300Pa |

| Max Single Bottle Weight | 60g |

| Single Air Blower Power | 2.2KW |

| Air Blower Voltage | 380V |

| Air Blower Rotation | 2900V/min |

|

Air Blower Distance |

8-9m |

|

Rated Airflow |

2500-3000m3/hour |

| Air Consumption | less than 0.5m3/hour |

| Air Pressure | 0.6-1Mpa |

| Average Energy Consumption of Air-duct | 250W/m |

Features

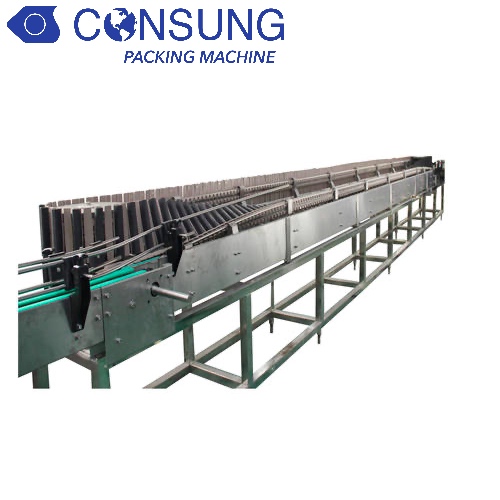

1.Air Duct: The air duct and all auxiliary parts of the air duct are made of stainless steel SUS304 luster plate, the tank plate is 1.5mm thick and the flange plate is 4mm thick, which fully meet the requirements of the food industry。The production of the air duct fully considering the convenience of maintenance,so as to ensure that there is a cleaning/access port within a range of at least 1.5m (except the bend and the upper and lower section of 12°),and the appearance of the air duct shell after the production is guaranteed to have no obvious scratches, strains and other phenomena.

Each duct has a quality tracking sheet for the whole process from production to assembly, and each procedure is completed in strict accordance with the factory standard。

2. Blow-mouth and duct bottom plate: Air blowing tunnel on 2 sides and top size, and no other wind guide device is needed inside the air duct。Make the air blowing outlet simple, easy to clean, and reliable and stable.

Air blower outlet and air duct bottom plate are the most important parts of the air duct, which are strictly controlled during the whole manufacturing and assembly process.

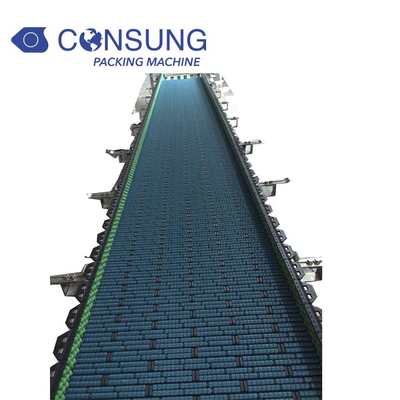

3. Bottle Clamping Strip: The bottle clamping trip hangs the bottle in the air duct and directs the transmission of the bottle. we adopts the imported brand of ultra-high molecular wear resistant bottle strip,Its good sliding, wear resistance and impact resistance are a great success for our fully grasping the transmission characteristics of PET bottles.

4. The AST bottle clamping strip is made in The United States, and calculated at 14,000 bottles per hour, ensure the using life of the strip in straight section ≥15000 hours;Our Company guarantees that the service life of the bottle clamping strip in the wind trough curve and the split confluence section is ≥9000 hours

5. China factory specializing in the production of Empty PET Bottles Air Conveyor