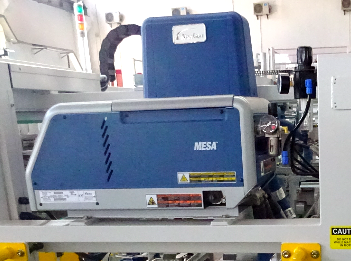

Hot melt glue machine operation for wrap around packer machine

I. Hot Melt Adhesive Machine:

1. Power switch POWER on, indicator light.

2. To drain the plastic and filter of the hot melt machine, the pressure of the pressure regulating valve shall be adjusted to the lowest when the material is blown, so as to ensure safety.

3. Pump pressure regulating valve (pressure is about 2 ~ 3Kg/cm2) the higher the pressure adjustment, the thicker and stronger the glue, the lower the adjustment, the finer and weaker the glue.

4. automatic gun pressure adjustment (pressure adjustment of about 5 ~ 6Kg/cm2).

5. barrel heating temperature adjustment (temperature about 350 degrees Fahrenheit).

6. nozzle heating temperature adjustment (temperature about 350 degrees Fahrenheit).

7. heating tube heating temperature adjustment (temperature about 350 degrees Fahrenheit).

II. Notes:

1. Wear safety eyewear, safety gloves (P/N 902-514) and protective overalls, which can prevent the burns on the surface of hot melt glue gun and the damage caused by hot melt glue.

2. When it is necessary to remove the filter, and opening the release valve, it should be used to relieve the pressure of the system and reduce the hydraulic pressure of the pump and spray gun to zero. If you forget the pressure,it will cause severe burns.

III. Removal method of Simple nozzle :

1. Wear gloves to remove the nozzle head, first use the pass needle to connect the nozzle from the outside to the inside.

2. Pick up the air gun and blow it from outside to inside.

3. Repeat this way several times.

( It only works when the nozzle is heated, if it's cold, you need to heat it up again.)

For detail, please refer to the operating instructions of the hot-melt glue machine.