- PRODUCT DESCRIPTION

- VIDEO

- INQUIRY US

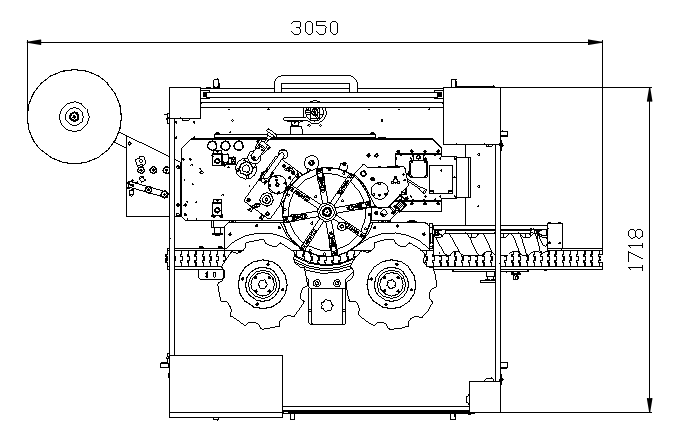

|

Model |

OPP-4L |

|

Speed |

8000-10000BPH (500ml) |

|

Power |

8KW |

|

Applicable Container Size |

round bottle dia.40-105mm height 80-350mm |

|

Applicable Label Size |

L 125-325mm H20-190mm |

|

Air Compression |

0.2m3/min |

|

Glue Consumption |

1KG glue for 100000 pieces bottle (Label Height is 50mm) |

|

Weight |

3000KG |

Features

1. Bottle Divider to make bottle coming one by one to label

2. Schneider PLC, touch screen, servo system to make sure the opp labeling machine more stable

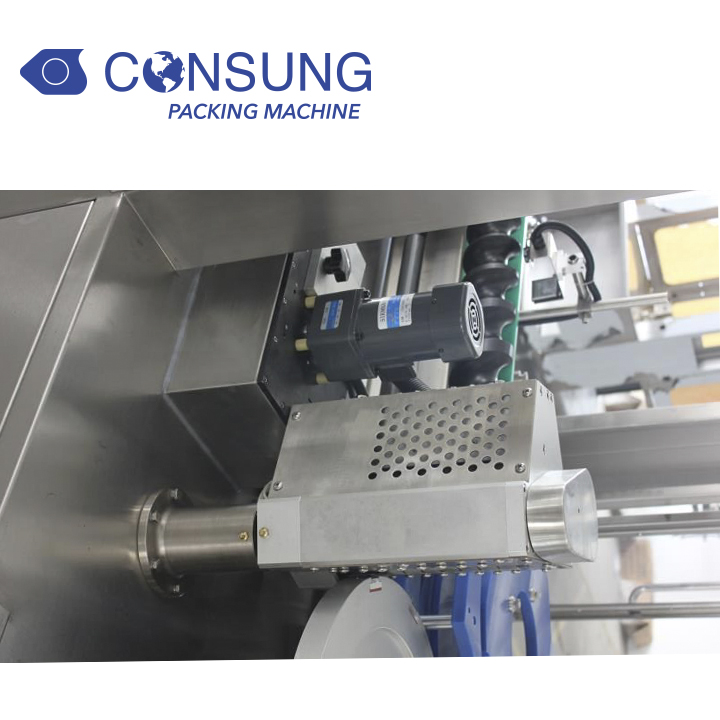

3. New Type Glue machine to provide glue to paste label on round bottle

4. One-shot lubricating system make the opp labeling machine more stable and extend lifetime.

5. Label for full wrap around bottle with hot melt glue

Main Description

First, the bottles on the conveyor chain enter the star wheel from the bottle-separating screw. At the same time, the servo motor drives the traction roller to feed the label to the cutter drum. The cutter drum absorbs the label through the vacuum generated by the vacuum pump, and the label is cut at the cutter. The labels are transferred to the labeling drum. When the label on the labeling drum is in contact with the glue roller, both ends of the label are instantly coated with hot melt adhesive. The labeling drum is then turned to the contact position with the bottle, and one end of the label is adhered to the surface of the bottle. Then, the bottle rotates in the space formed by the labeling drum and the bottle-rubbing mechanism, and the other end of the label is then adhered to the surface of the bottle. Complete a labelling process.

Sensors for detecting bottles and labels are installed at the bottle feeding screw and traction place, and an encoder is installed under the cutter drum to provide signals for the control system to determine whether the servo motor will feed the BOPP labels (no bottle will not feed the BOPP labels) and Whether the rubber roller is glued (no label is not glued). This determines the movement of each part of the machine.

Machine Details

Case

Automatic Linear hot melt glue labeling machine for PET Bottle Oil Bottle for South Africa Customer

Automatic Wrap Around Glue Labeler Machine for Yemen Customer