|

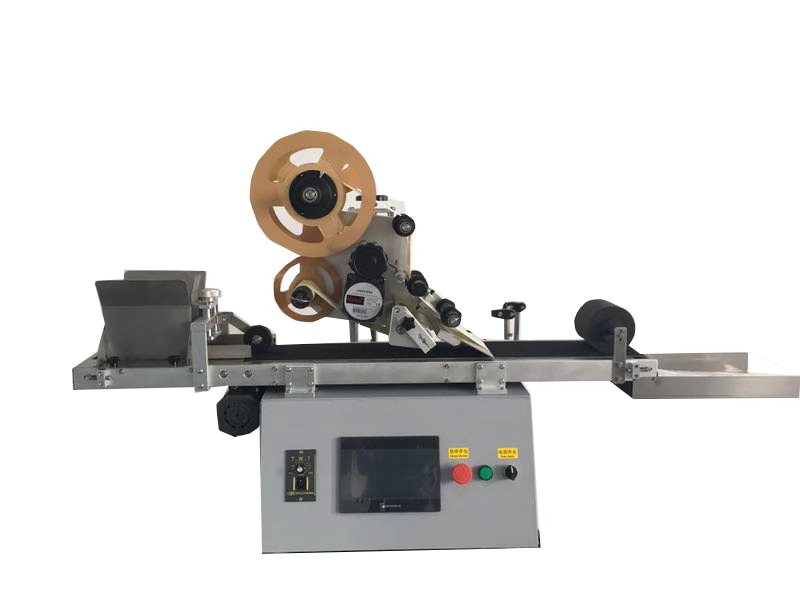

Model |

BGJ-F300 |

|

Label Material |

Label Roll Paper |

|

Labeling Precision |

+/-1mm (exclude the product label deviation) |

|

Labeling Speed |

60-150pcs/minute(its up to product size) |

|

Applicable Bag Size |

various sizes of bag 100≤bags width≤280mm, length modification |

|

Applicable different self adhesive labels Sizes |

10≤label width≤130mm |

|

Power |

220V, 50/60HZ |

|

Weight |

185KG |

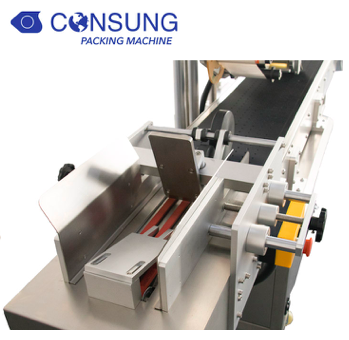

1. Bag Separating Device/bag loading platform (human operator hand feeding bags on feeding pouches device ) can feeding different size of pouches(no need to install changeover) to convey bag to automatic labeling process

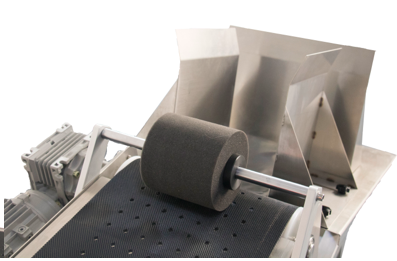

2. Labeling Press System&Bag Collect System can make sure labeling effect by pressing label double times, and can collect finished bag in table

3. It is controller by motor and PLC which labeling machines labeling speed can reach 60-150 pieces per minute and also cost efficient

4. Labeling Machine manufactured by consung is widely used in food, medical, chemical and cosmetic industry and accent packaging equipment

5. Our quality plastic bag labeling machine is most cost effective label applicator, it has accurate label applicator which can do good labeling job and missing label detection.

6. Installation successful in factory, Easy to improve efficiency and user friendly

7. The main materials of the labeling machines are SUS304 and high-grade aluminum alloy, the overall structure is firm, beautiful and easy to operate and maintain

8. The scope of application of the label applicator is customized according to customer samples, the labeling accuracy is +1mm, and the size of the applicable products can be adjusted arbitrarily within the technical specifications, our standard labeling machine conveyor wide is 280mm, label width is less than 130mm, but if customer product exceed our standard range, we can customize labeling machine according to customer label width and product width. or customer can choose our semi automatic labeling machine.

9. Our bag labeling machine has a small structure and small footprint, which is convenient for equipment movement and placement; the equipment includes positioning device, fault alarm function, production counting function, printing function, etc. (reserved)

10. Plastic Bag Labeling Machine Function: automatic detection and labeling, improve the sticking efficiency of product labeling, accurate sticking position, good quality and high stability; avoid low efficiency of semi automatic labeling, sticking skew, blistering and wrinkling, irregular sticking position, etc. series of problems; effectively reduce product costs, improve product label logo aesthetics and high stability, and enhance product competitiveness

11.Plastic Bag Labeling Machine applicable product range: carton, flat bottle, round bottle, square box, etc. cylindrical/flat body labeling, flat bags, flat surface products, bar code, electronic supervision code, classification label, etc.

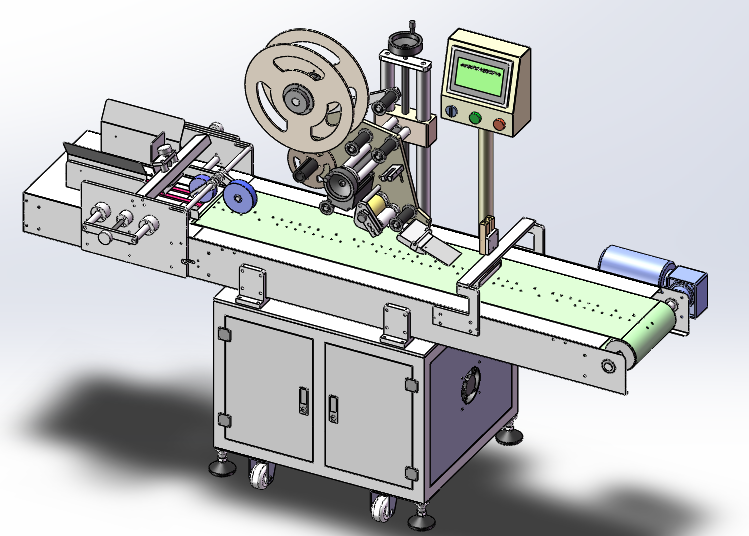

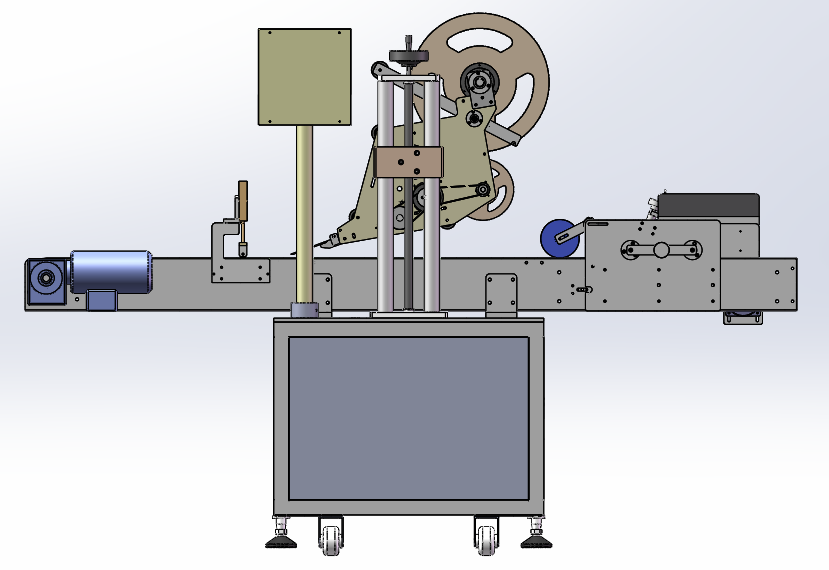

Machine Descriptions

The automatic page labeling machine is not semi automatic we build is mainly composed of label feeding, label applying, bags delivery, fully adjustable guide, bags collection and other institutions. This manufactured equipment is independently developed and accent designed by the company, which can realize automatic labeling on both sides at the same time. The original labeling process and efficiency are improved, the labeling effect is more accurate, beautiful, and the error rate is lower. This equipment is customized according to customer requirements.

This model is suitable for industries: electronic accessories, food chemicals, electrical accessories, hardware electromechanical, auto parts, printing and packaging and other industries

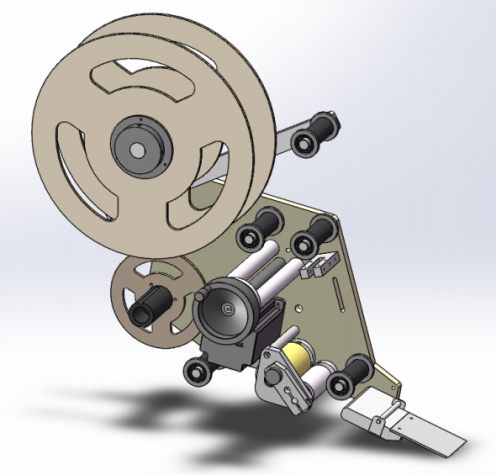

1. The automatic and semi automatic labeling machine head is composed of label pulling, paper receiving, label supplying from label roll and other institutions, and the main components of the labeling mechanism.

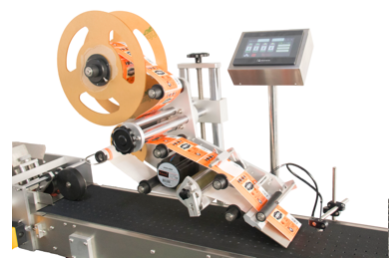

2. The touch screen of the labeling machine displays and adjusts all the information and content of the labeling part.

3. Emergency stop switch Power switch The power switch is used to turn on and off the power supply of the labeling machine, and the emergency stop switch stops the operation of the equipment in an emergency.

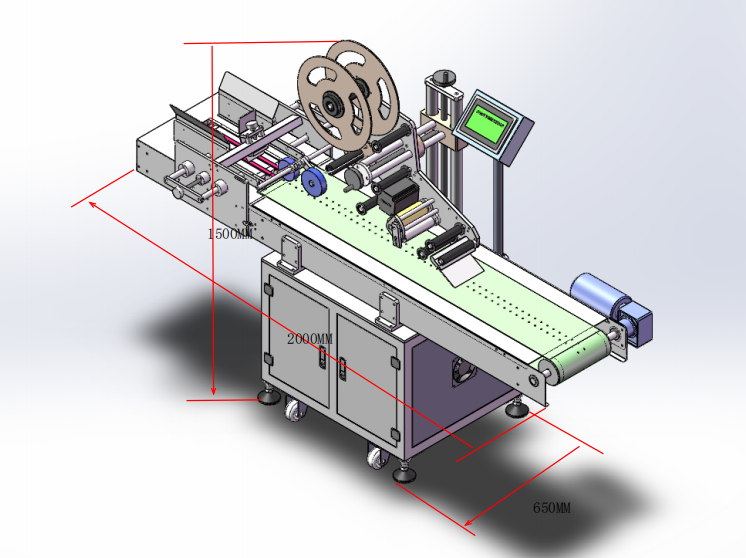

4. Conveying mechanism make the product transport smoothly, complete the whole plastic bag labeling, stainless steel material, the overall length is 2000MM.

5. Labeling electrical control cabinet Install all the electrical appliances of the plastic bag labeling mechanism inside, with a lock, which needs to be openable.

6. Conveying motor 180W turbine frequency conversion motor, which is the component of the entire conveying mechanism.

7. Exhaust fans are provided on both sides to dissipate heat from the electrical appliances inside the chassis.

8. For the label supplying plate used to place the whole roll of labels, made of plexiglass, with both positive and negative labeling machine heads.

9. Back Label Take-up tray is used to collect the label waste paper after use. It is made of plexiglass and has both front and back labeling machine heads.

10. Horizontal adjustment mechanism It is used to adjust the horizontal width of the host, which can be adjusted arbitrarily according to different labeling positions.

11. Plastic bag labeling Label pulling mechanism It is composed of label pulling wheel, eccentric wheel and other parts, and there are both positive and negative labeling machine heads.

12. Label pulling motor Imported servo motor, the main function is to detach the label from the bottom and stick it on the product, with front and rear labeling machine heads.

13. The label peeling plate is made of stainless steel, which makes the label separate from the backing paper.

14. The tape guide rod is made of stainless steel and POM material to make the label transition.

15. The label detection photoelectric bracket is made of aluminum alloy, and the label detection fiber is installed to detect the identification label.

16. Brake rocker arm The brake device that controls the start and stop of the bid-supplying mechanism.

17. The lifting mechanism of the main machine is used to adjust the upper and lower height of the labeling main machine, which can be adjusted arbitrarily according to products of different heights.

18. Chassis support feet After the device is moved to a fixed position, tighten the support feet to place the device to move.

19. The chassis casters can be rotated 360°, which is convenient for the equipment to move.

20. Touch screen fixing bracket The mounting bracket used to fix the human-machine touch screen.

Machine Details

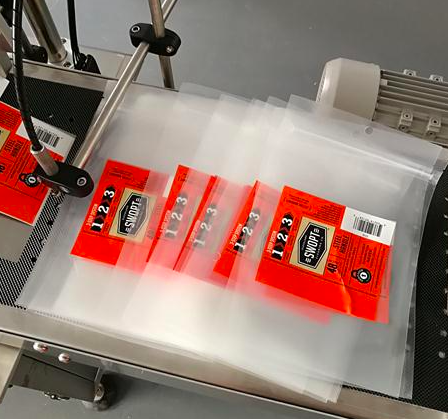

Samples Photos

|

|

|

|

Packing Photos

Case

Name: Labeling Machines BGJ-F300 1 SET

Country: France

Industry: Medical

Details: The label applicator is to separate medical bag automatically, applying labels from label roll automatically, collecting automatically

Name: Self Adhesive Labeling Equipment 1 SET

Country: Romania

Industry: Food

Details: Our label applicators are automatic not semi automatic, which include label to for empty plastic

bag. function is from bag dispenser, bag labeling and bag collecting

More Cases for your reference

PE bag labeling machine testing video

Automatic cardboard dispenser feeding and labeling machine

Zipper Pouch Bag Labeler Machine

After-service assistance

Normally this model label applicators dont need to install and commission, customer only need to connect with power and run machine, but if customer require engineer to their customer factory, We will send one engineer from our factory to customer’s factory for installation and commissioning and training, customer should be responsible for the room and board and the go-back air tickets and visa fee, and the allowance of 100 USD per day for each person each day.

Customer also can send your engineer to our factory, we will provide one engineer to teach you how to install and commissioning machine for free.

Training assistance

We will provide technical training for our customer. Training content include equipment structure, maintenance, control and operation. We will appoint a qualified technical personnel to guide. Through training, your technical engineer can master operation and maintenance skills, skillfully adjust process and deal with all fault in time.

Spare parts assistance

To make sure flat bags labeling machine’s stable and high efficiency running, it is necessary to use our machine’s original spare parts, we have a large number of spare parts for different machine, so customer can easily receive our spare parts at first time.

Online assistance

We will provide 24hour online technical support by wechat, email or whatsapp, etc. when customer met some problem during our labeling machine operation, customer provide machine video, picture to list problem, we will solve problems for you within 24hours