|

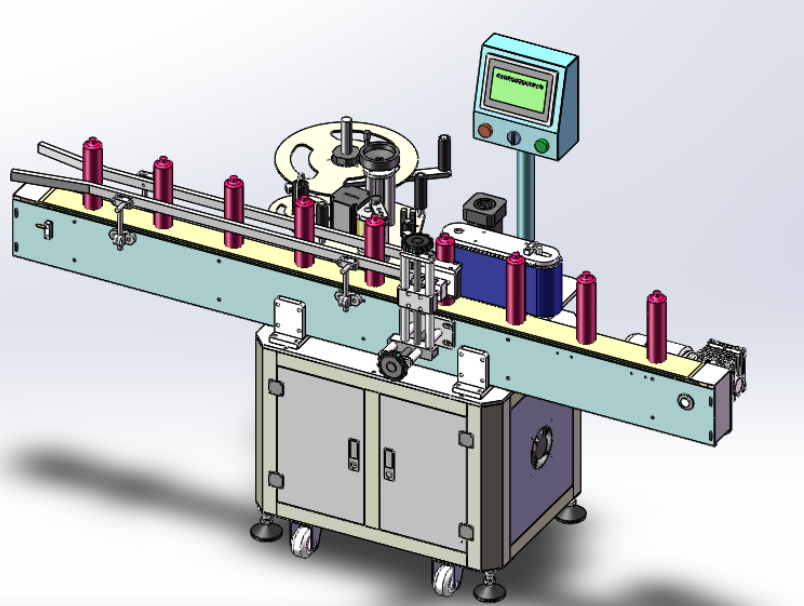

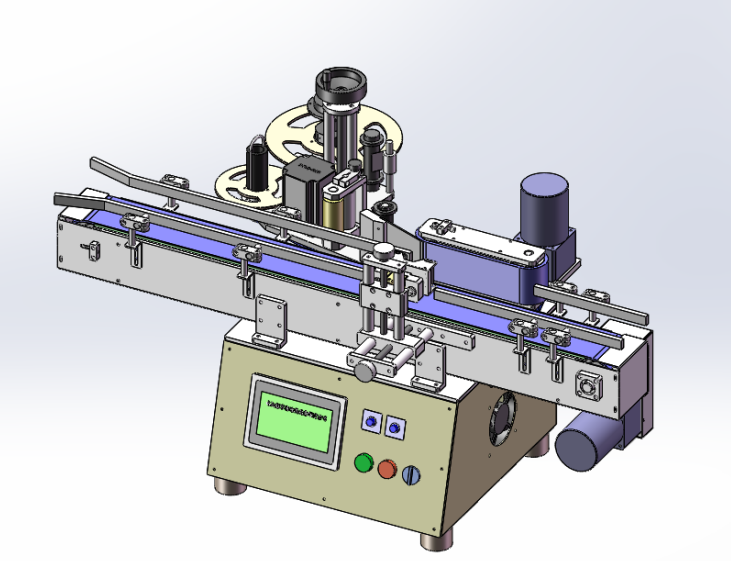

Model |

BGJ-Y400 |

|

Labeling Speed |

0-400bottle/min |

|

Labeling Precision |

+/-1mm |

|

Label Length |

25-200mm |

|

Vial or Ampule Size |

customized |

|

Power |

220V, 50HZ |

|

Weight |

500KG |

Features

1. It is specially for pharmaceutical labeling system to make small diameter glass bottle labeling.

2. It consists of rotary table vial, ampule bottle feeder, high speed vial labeling machine, product accumulation table

3. Servo motor control, PLC to make sure fast labeling

4. This equipment is specially used for the labeling of round bottles.

5. The labeling machine head is a three-stage labeling system, which is divided into label supply, label pulling and bottom paper recycling systems. Each system is controlled by a separate motor to ensure fast and stable label supply and labeling speed. with precision.

6. The bottle dividing mechanism adopts stepless speed regulation, and the separation distance can be arbitrarily set according to the product specifications. The bottle-rejecting mechanism is installed in front of the bottle dividing mechanism to ensure the stable operation of the equipment.

7. The bottle feeding mechanism adopts a turntable track feeding mechanism, with stable feeding and large buffer space.

8. The wheel-attached rolling bottle body makes the label attach more firmly.

9. The rear collection platform facilitates the collection, arrangement and packaging of finished products.

10. Touch-sensitive man-machine interface, any abnormality can be displayed on the man-machine interface and guide troubleshooting. The operation is simple, and anyone can use the device quickly. There are 50 sets of memory functions (including parameters such as bottle diameter and labeling length), which do not need to be reset when changing products of different specifications, and can be called directly, which greatly improves work efficiency.

11. Multi-point emergency stop buttons can be installed, and emergency stop buttons can be installed at appropriate positions on the production line to ensure safe operation and smooth production.

12. The label peeling distance is automatically calculated by the servo motor, label detection photoelectricity and PLC. There is no need to adjust the label detection photoelectricity position. Any label length can be modified on the man-machine interface, which is convenient to use.

13. No label, broken label, missing label, no ribbon alarm and automatic shutdown, no bottle without labeling.

Label Requirements

The non-drying label parameters (for reference) :

1. Label pitch: 2-4 mm ± 0.2 mm

2. Below on the label and the bottom paper spacing below: 2 mm

3. Bottom paper: need not less than 62 grams of white gration bottom paper, paper density and has very good internal strength and light transmittance, solid and not easily torn. Die cutting performance is wonderful.

4. Basic gram: greater than 62g/㎡ thickness: greater than 55 microns

5. Tensile strength: machine direction: 16kg/25mm

6. Cross to: 7kg/25mm

7. Tear resistance: machine direction: 25g/sheet

8. Cross to: 31 grams/sheet

9. Through the brightness: 52%