Latvia customer order automatic bag labeling machine

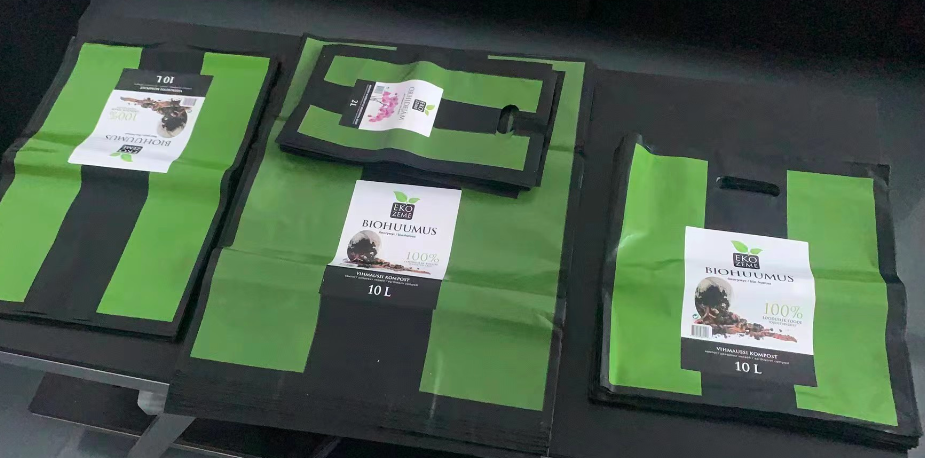

Our customer is producing organic fertilizers and substrates in Latvia (LV). For packaging our products they use different size plastic bags with labels on both sides. Up till now they are putting labels on bags manually, but as their sales increase more and more they are looking for labeling machine.

they have found our contacts on youtube where they saw a machine similar to what they need (https://www.youtube.com/watch?v=k5o-9dswrVI).

Main requirements and characteristics are as follows:

Bag film thickness: 50 – 80 mic;

Plastic bag sizes (width x length): 200 x 350; 330 x 380; 330 x 500;

450 x 600 mm, (600 x 900 mm);

Label sizes (width x length): 100 x 137; 104 x 113; 148 x 210 mm,

(180 x 270 mm);

Labels roll inner diameter: 76 mm;

Labels roll outer diameter: 250 - 300 mm;

Label roll carrier max. load: 3,0 kg;

Transporter width: 600 mm;

Bag supply from the stack: from top;

Bag supply tray (width x length) 600+ x 900+ mm (with adjustable side

walls);

Bag supply tray max. load: 5,0 - 7,0 kg;

Bag receive tray (width x length) 600+ x 900+ mm (with adjustable side

walls);

Bag receive tray max. load: 5,0 - 7,0 kg;

Labeled bags counter.

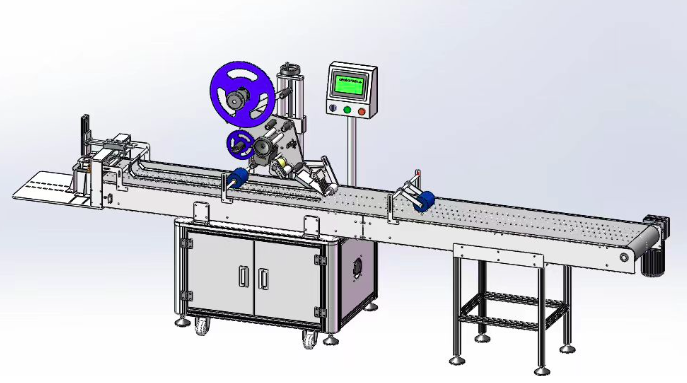

About above requirements, we recommend our BGJ-F300 bag labeling machine to customer, but make some changes according to customer requirements.

Through two weeks confirmation, customer confirmed order for customized bag labeling machine, thanks your believe.

Following is our customized labeling machine pictures

Following is bag sample pictures

Following is testing video with customer samples