How to adjust the linear hot melt adhesive labeling machine

1.Name of the facial parts of the linear hot-melt glue labeling machine

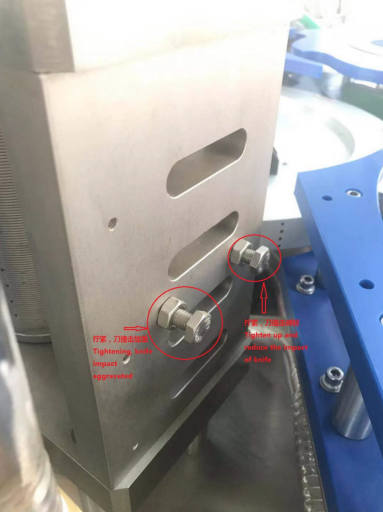

2.cutter group adjustment for hot melt opp glue labeler

The cutting knife group cuts off the label and feeds the label to the suction roll. The clamping label is impacted by the moving knife and the static knife, and then the label is stably transported to the suction roll by the combination of suction and blowing.

As shown in the figure, the bed knife adjusts the angle and the level of the movable knife by screw to ensure that the whole knife can cut off the label as far as possible.

When the level of the stationary cutter and the moving cutter is horizontal, the impact force between the moving cutter and the stationary cutter is adjusted by changing the angle of the stationary cutter roll.

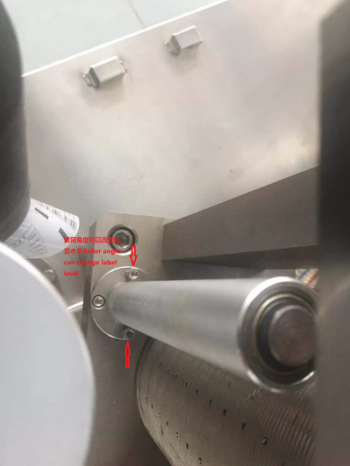

Cutter drum: small change in the horizontal position of the label in the suction roll

3.Glue coating group

Function: Melt the glue and apply it evenly on both ends of the label.

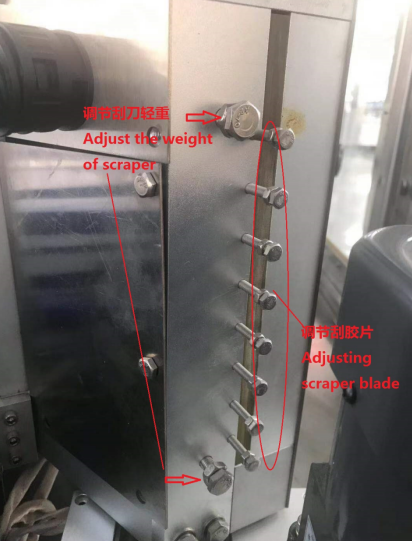

4.Scraper group

Function: Adjust the glue amount on the Rubber roller

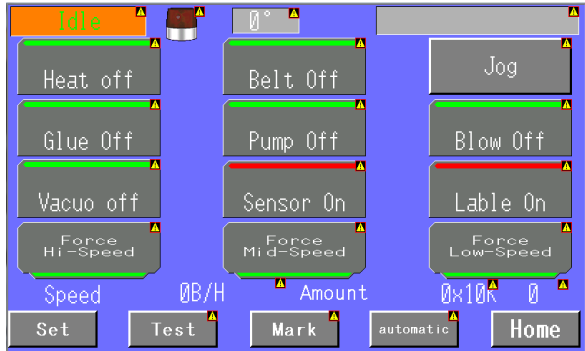

Operating screen instructions (different appliances)

1.Description of Schneider 101 Electrical Display Screen

Heat off/on: Heating control switch

Jog : Point motion mode

Glue off/on : Control of Glue-coated Cylinder

Pump off/on : Rubber pump motor switch

Blow off/on : Blow solenoid valve control switch

Vacuo off/on : Vacuum pump switch

Sensor on/off : Color label sensor switch(Close this button with fixed length marking)

Label on/off : Bid Feeding Control Switch(Closing this button will stop the bid delivery.)

Force Hi-speed/Mid-speed/Low-speed : Forced Speed Control, High, Middle and Low Speed Set by High, Middle and Low Corresponding Parameters

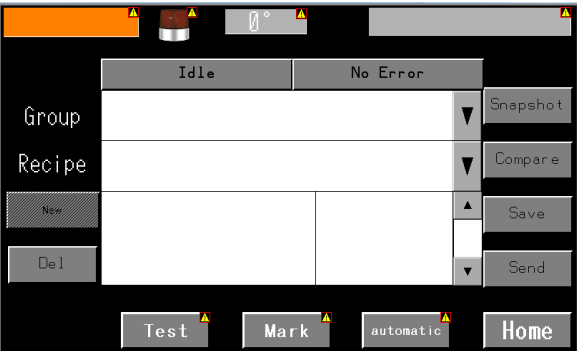

2. Parameter setting interface

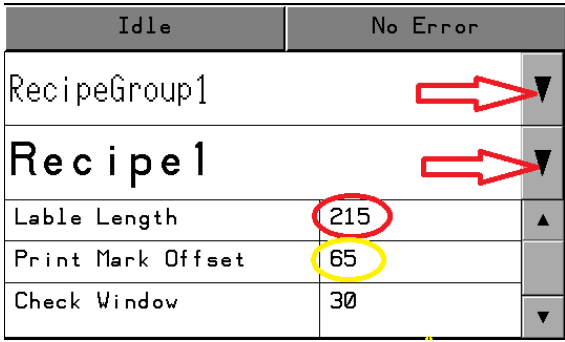

The parameter setting interface mainly sets and saves label related parameters, different label lengths and offsets corresponding to different bottle types.

Label Length : Label length, set value must be consistent with actual label;

Print Mark Offset :Change the notch position of the label, the value should not exceed the total length of the label, and the actual value should be adjusted according to the actual label.

Check Window : Normally default 30 does not need to be changed

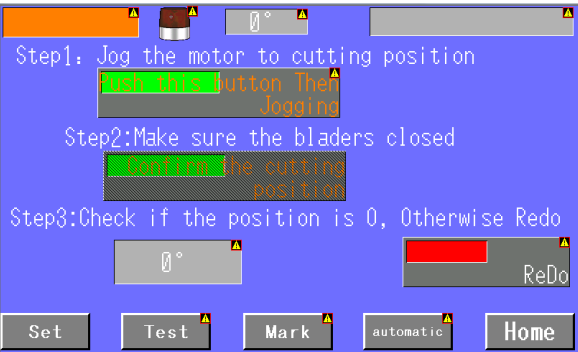

3. Serach interface

When the label problem occurs: the label incision position is not right, the label length gap is too large. Re-referencing to correct label problems

Steps 1-3 are knife operations, which usually do not require settings. If there is a problem with settings, follow this step. When the cutting edge wants to touch, the cutting edge angle is zero, then the cutting edge is normal.

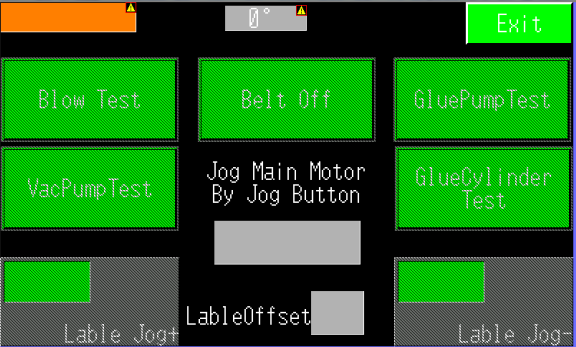

4. Single action page

Jog Main Motor By Jog Button : Point Speed Settings(Set the running speed of the machine when it is in point motion)

Label off set :Change the value if the first bottle is misaligned with the first label

2.Schneider 26 Servo Display Screen

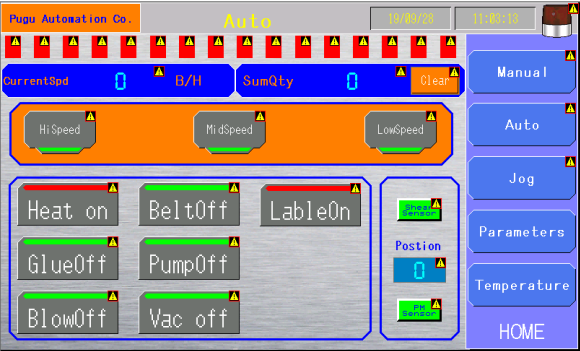

1.Automatic Page

Heat off/on: Heating control switch

Jog : Point motion mode

Glue off/on : Control of Glue-coated Cylinder

Pump off/on : Rubber pump motor switch

Blow off/on : Blow solenoid valve control switch

Vacuo off/on : Vacuum pump switch

Sensor on/off : Color label sensor switch(Close this button with fixed length marking)

Label on/off : Bid Feeding Control Switch(Closing this button will stop the bid delivery.)

Force Hi-speed/Mid-speed/Low-speed : Forced Speed Control, High, Middle and Low Speed Set by High, Middle and Low Corresponding Parameters

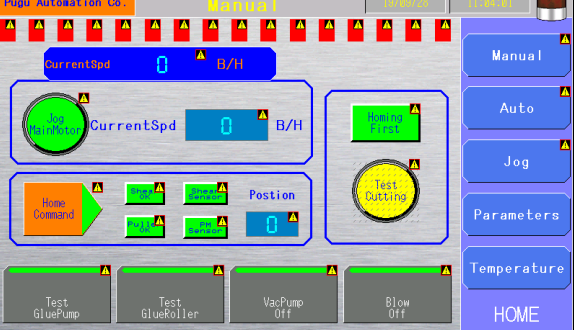

2. Manual Page

Home Command : Zero-finding, in the color label mode, to make label parameters effective, can also solve most of the label problems.

Before automatic operation, zeroing operation should be performed after the parameters of the label are determined, and zeroing operation should also be performed when the label-related alarm occurs.

Signal indicator bar, when the bottle entry sensor detects the signal, the indicator bar will turn blue

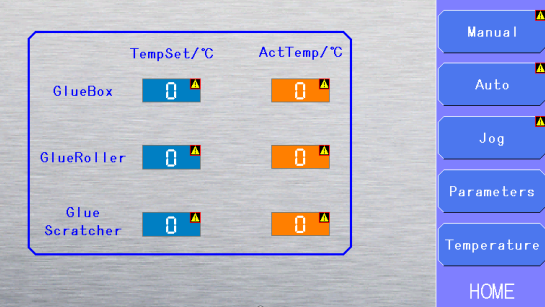

3. Temperature Setting

The default setting is 150, which can be adjusted according to the actual environment.

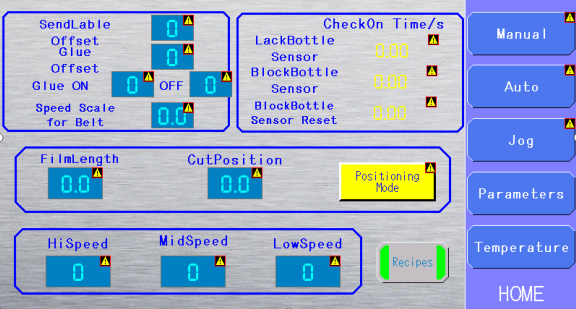

4. Parameter Setting Page

Send Label offset : Change this parameter when the label does not correspond to the bottle

Glue offset : Change this parameter when the glue action does not correspond to the label

Glue ON : Change Glue Angle

Speed Scale For Belt : Conveying speed coefficient, the greater the value, the faster the speed.

Film Length: Label Length Setting

CutPosition:Change of Label Incision Position

Positioning Mode:In this mode, the length of each tag is the same and the position of the incision is random.

PrintMark Mode:In this mode, the length of each label is the same, and the position of the cut depends on the offset of the color label

Daily production attention

1. Turn on the power of the machine, wait for the PLC to start completely, turn on the heating button in the screen。 Heating usually takes 30-50 minutes to complete.

2. Make sure the label is firm on the label plate. Manually pull the label to confirm that the color label sensor senses normally. Call out the corresponding formula, save, download and search for parameters.

3. Cover the sensor in the bottle, open the air blowing and vacuum pump, operate the machine in the point mode, observe the state of marking, 4-5 labels in a row can be normal.

4. Remove the occlusion of the sensor entering the bottle, click on the signal label to remove the occlusion by hand, open the conveyor, and switch to automatic mode to start.

Be careful:

①Each bottle feeding signal corresponds to a label.

②Label problems should be checked to see if the suction roller is glued.

③Label problems should be Search for parameters.

④The label should be level and stable on the suction roll.

⑤Keep bid delivery stable, tight and not loose

⑥The glue can not be opened until the label is on the suction roll.

⑦Bottles must be continuous at high and high speeds.

⑧Maintain daily cleanliness and weekly maintenance as much as possible