How to choose a suitable shrink packaging machine?

1. Determine the form of the items you want to pack. Generally speaking, the packaging form of shrink packaging machine is divided into two types, one is fully enclosed type, and the other is cuff type. The closed type is all wrapped, such as milk or cosmetic boxes on a plate, and the cuff type is a small opening on both sides, which is generally used for beverages, mineral water, beer, etc. These two types of shrinking machines are different, so be sure to determine the packaging form of your items.

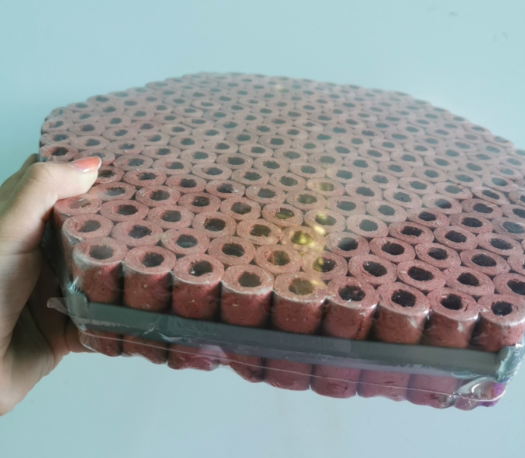

2. Determine the packaging film you use. There are generally three kinds of packaging films, POF, PE, and PVC. Generally speaking, PE film is the thickest and is generally used for beverages. POF and PVC are generally used in cosmetics, gift boxes, mobile phone boxes and other items. The price of the PE film shrinking machine is relatively high, and the others are relatively cheap. The PE film shrinking machine can shrink other films, but it cannot be sent, because when the PE film shrinks other films, the temperature can be lowered and the speed can be accelerated. But in turn, not only affects the speed, the effect is not ideal.

3. Determine the size of your items. Different models of shrink wrapping machines have different sizes of shrink furnaces, so you can choose the most suitable one after determining your own size.

4. Look at the load-bearing capacity of the shrinking machine. According to the different items to be shrunk, the load-bearing capacity of the shrinking machine is also different. Some are up to 20KG and some are 50KG. Therefore, you must pay attention to the problem of load-bearing when purchasing. If the load-bearing is too light, the service life of the machine will be greatly shortened, or even impossible Use, if it is too heavy, the cost will increase

5. Semi-automatic or fully automatic choice. A semi-automatic shrinking machine generally has only one shrinking machine. If it is a fully automatic shrinking machine, there is a film sealing and cutting machine in front. Generally choose fully automatic machinery

6. Look at the shrinkage effect. If you can, bring your own items to the seller and test it out to see if the effect is satisfactory.

7. Heating method. The heating method of the shrinking machine is different, some are quartz tube heating, and some are steel pipe heating. Is the former cheaper and the latter more expensive, but the quartz tube is a wearing part in the shrinking machine, and it is easier to damage, but the steel pipe is not easy. damage.

8. Look at the price. The market's shrinking machine, whether it is the lowest price or the highest price, will never break through a "degree". Try not to choose the cheapest one, especially the price is unbelievably cheap, because this type of machinery is likely to have problems. If you don’t pay special attention to the brand, you can choose a middle price. The price of the shrinking machine of the general brand is relatively high.

Precautions

1. Those who are uneasy about the effect are best to go to the factory to try the effect in person

2. Many items can be shrunk, but need to be customized.