What factors and routine maintenance should be considered when selecting conveying equipment

In order to ensure the reliable operation of the conveying equipment, we need to consider the following two aspects when selecting the conveying equipment: consideration of the selection of conveying equipment and environmental conditions.

Since the surface of the transported material is in direct contact with the conveyor, the characteristics of the item will also directly affect the selection of equipment and the design of the system. The characteristics of the materials we are transporting include weight, surface characteristics (soft or hard), packaging methods, dimensions, and processing rates are all factors we have to consider. All materials that need to be transported need to list the size and weight of the volume and whether there is a seal, which will affect the selection of conveying equipment; for example, materials with a light weight are likely to make the sensor inactive, and materials with a large volume will also It affects the selection of conveying equipment types, such as roller type or belt type, and the size of the roller and belt is determined by the material. For some accumulative conveyors, the weight of the material and the range of distribution also have a significant impact.

Most of the conveying equipment is indoors, and the indoor (warehouse) environment is generally operated with lights and air conditioners. If there is extreme temperature, special selection of bearings, belts, drive sheets, etc. is required. The indoor environment where the conveying equipment is located is relatively clean, but the conveying equipment system may also have to be connected in a very clean area or in a harsh environment (such as a waste carton area). Whether the characteristics of the material are based on safety and health factors must be isolated, and these factors are also closely related to the design of the conveying system and the storage area.

All material handling equipment requires irregular maintenance and maintenance. For more complex systems, the manufacturer should provide regular maintenance measures, while for gravity systems, only regular inspections are generally required. to ensure the normal operation of the rollers. Enterprises will prepare fixed maintenance personnel for inexpensive manufacturing equipment to ensure the normal operation of the conveying equipment. In the preliminary planning stage of the enterprise, compared with the complex moving system, the maintenance cost also needs to be included in the procurement budget, and the maintenance requirements must also be included in the system selection and evaluation considerations.

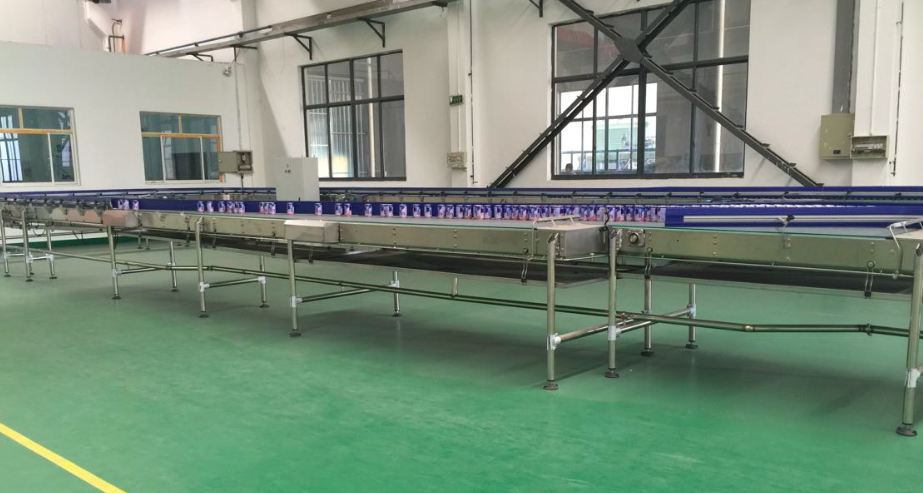

Conveying equipment plays a very important role in the production of today's industrial enterprises. The quality of the conveying equipment will also directly affect the production process level and production efficiency of each production enterprise; it is also an important link that reflects the entire production process of each industrial enterprise. Therefore, it is necessary for each production enterprise to carry out long-term and daily cleaning and maintenance of the conveying equipment to ensure that the conveying equipment can carry out safe and stable conveying operation and achieve the purpose of increasing the normal service life of the conveying equipment.

When the production enterprise uses the conveying equipment in production, it should be selected according to the type, characteristics and use capacity of the conveying system and equipment selected, and at the same time, it should be selected according to the nature of the conveyed material. Because it contains materials of different nature, it will determine what type of conveying equipment to choose and what kind of production and conveying operation environment, and also what kind of operation environment the conveying equipment is in. When the conveyor belt of the conveying equipment is worn and aged, it must be replaced in time. Don't wait until it breaks, thinking about replacing it, otherwise it will cause serious wear and tear to the conveying equipment, which will affect the conveyance. The mechanical performance and service life of the equipment.

In order to enable the conveying equipment to better ensure the smooth conveying operation at a safe temperature in the production and conveying operation, the most important thing is to discover and eliminate the faults of the conveying equipment in time. , in order to better ensure that the operator avoids the mechanical failure of the conveying equipment caused by illegal operations when using the conveying equipment.